The Importance of Hydrogen in Chemical Manufacturing

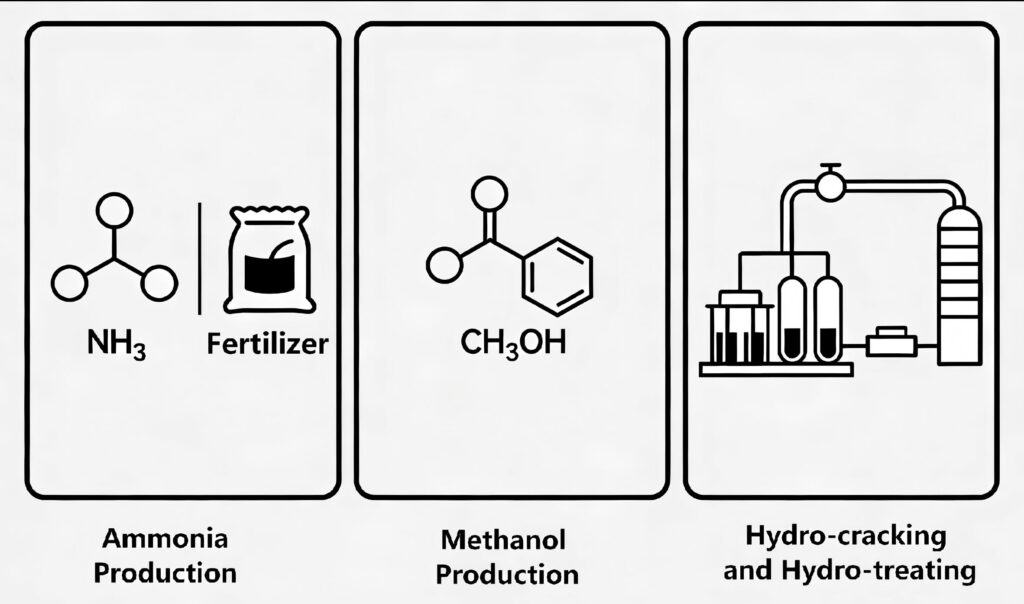

Hydrogen plays a vital role in the chemical sector. It serves as a key raw material for essential tasks, including the production of ammonia, methanol, and oil refining. For ammonia production, hydrogen mixes with nitrogen at high pressure and heat over an iron catalyst. This forms ammonia, which is a basic component in fertilizers. Methanol facilities combine hydrogen with carbon monoxide or dioxide. They use catalytic reactions to produce methanol. In refineries, hydrogen helps with hydro-cracking and hydro-treating. These steps enhance fuel quality and reduce sulfur.

In every one of these uses, the cleanliness of hydrogen matters a lot. High-purity hydrogen ensures stable reaction kinetics and protects sensitive catalysts. DINAK knows how important gas purity is. Our company supplies modern purification setups made just right for chemical producers' tough needs.

Challenges of Impure Hydrogen Supply

Trace contaminants in hydrogen can cause big problems in chemical work. Trace contaminants such as sulfur compounds (H₂S, COS), moisture, and hydrocarbon carryover can severely poison industrial catalysts. This cuts their power and shortens their life. As a result, plants often swap out catalysts. Costs go up from this.

What's more, dirty hydrogen speeds up rust in pipes and reaction vessels. This brings sudden breakdowns and safety dangers. If gas flow varies or purity dips, processes get shaky. Alarms go off, product standards slip, or plants shut down in emergencies.

DINAK’s Role in Ensuring Reliable Hydrogen Purification

DINAK focuses on hydrogen purification solutions that support steady and safe work in chemical areas. Our setups stand strong. They also run with high automation. This keeps things going well, even in tough spots.

Our industrial furnace exhaust gas recovery system recovers hydrogen from off-gas streams. It collects them, cleans them up, improves them, and pumps them up. Then, these gases return to the production line for reuse. This way saves resources. It also gives a steady gas flow with even purity.

Hydrogen Purity and Industrial Requirements

Purity Standards in Ammonia and Methanol Production

In making ammonia, things like oxygen compounds or sulfur can harm the iron catalyst in the Haber-Bosch method. So, hydrogen lacks these. The same holds for methanol making. It's very touchy to moisture (H₂O) and oil bits. Too much moisture (H₂O) shifts the reaction balance and catalyst choice. This drops the plant's overall work rate.

Refining Industry’s Sensitivity to Gas Quality

Refineries use a lot in hydrocracking and sulfur removal. These jobs need costly catalysts like platinum or nickel. Such materials hate trace contaminants. Moisture (H₂O) and sulfur turn off these catalysts. They also eat away at gear.

In many hydro-processing applications, sulfur levels can significantly reduce catalyst lifetime, depending on operating conditions and catalyst formulation. DINAK gives full gas separation and purification options. These keep high-quality hydrogen coming steady for smooth refinery runs.

Risks of Impure Hydrogen Supply

Catalyst Poisoning and Performance Loss

Tiny impurity levels can lock up catalysts for good. In most cases, poisoned ones can't come back. Plants replace them fully. This means long stops and big money losses.

Equipment Corrosion and System Failures

Moisture (H₂O) and acid-like trace contaminants speed up the eating away at pipes, heat exchangers, and reaction pots. This weakens the built strength. Over time, it breaks safety rules.

Impact on Product Quality and Process Efficiency

If hydrogen quality swings or drops below spec, reactions make poor goods. Uneven inputs cause a lot of differences. This might need redoing batches or tossing them out. Profits take a hit.

DINAK’s Hydrogen Purification Solutions

Robust System Design for Harsh Environments

Our hydrogen purification systems use materials that fight rust. They handle hot temps and harsh chemicals. The modular design fits right into current chemical sites. DINAK’s systems come in modular skid-mounted forms. This speeds up installs and trims build costs.

High Automation for Operational Continuity

Smart control setups drive every DINAK fix. They watch gas makeup live. This spot shifts right away. Auto cleanouts and refresh cycles cut human work. Errors drop from this. The system supports PLC-based automated start-up and shutdown, with remote monitoring via DCS integration. It allows far-off watching and issue spotting.

Reliable Gas Supply Under All Conditions

To avoid breaks, our builds add backup parts like two fans or pumps. This keeps gas flowing, sure, key for non-stop production spots. The system uses variable frequency fans—one working, one ready. It tweaks the air amount live based on furnace states.

Enhancing Safety Through Purification Technology

Prevention of Hazardous Reactions from Contaminants

Some trace contaminants, like oxygen bits or salt types, can clash hard with hydrogen in work conditions. These contaminants are removed through controlled purification processes, significantly reducing the risk of uncontrolled or hazardous reactions.

Compliance with Industry Safety Standards

DINAK’s equipment meets global safety rules for chemical spots. Built-in alerts and auto-stop steps add safety layers. DINAK supplies full auto systems with smart checks. They guarantee safe runs over long hauls. Over the past 20 years, DINAK systems have supported many chemical plants in meeting international safety and compliance requirements, thanks to these features.

Applications Across the Chemical Industry

- Ammonia Production Facilities: Our systems hold steady hydrogen purity. This backs good work in high-pressure loops common in ammonia sites.

- Methanol Synthesis Plants: DINAK’s purification units control trace contaminants just right. They let fixed-bed or slurry methanol reactors do their best.

- Petroleum Refineries: We back refinery hydroprocessing with a pure hydrogen supply. It's vital for upgrading, such as hydrocracking and hydrotreating.

We offers full solutions in our industrial gas solution lineup. These include hydrogen recovery systems fit for refinery spots.

Conclusion

DINAK’s advanced hydrogen purification systems tackle the main issues in chemical making. These include catalyst lockup, gear wear, safety threats, and uneven yields. Through solid build methods and smart auto tech, we provide a reliable gas supply. This lets clients in ammonia making, methanol creation, and oil refining run safely, smoothly, and with less cost. With more than 20 years honing gas handling tech, DINAK stays dedicated to custom fixes that lift plant edges around the world.

FAQ

Q: Why is high-purity hydrogen important in ammonia production?

A: High-purity hydrogen prevents catalyst poisoning in ammonia synthesis reactors, ensuring optimal yield and minimizing downtime due to catalyst replacement.

Q: How does impure hydrogen affect refinery operations?

A: Contaminants like sulfur or moisture can corrode equipment or deactivate catalysts used in hydro-cracking or desulfurization processes.

Q: How does hydrogen purification improve process safety?

A: Removing hydrogen impurities reduces the risk of hazardous reactions or equipment failure that could lead to accidents or regulatory violations.

-430x247.jpg)

内页小-430x246.jpg)