The Role of Oxygen in Smelting

In the metallurgical field, oxygen plays a crucial role in enhancing combustion processes. PSA oxygen generation technology is known for its flexibility and cost-effectiveness. It supports many sectors. For oxygen-enriched combustion, it works well in glass furnaces and metallurgical kilns. There, it raises combustion efficiency, cuts fuel use, and lowers carbon emissions.

Challenges with Traditional Oxygen Supply

The usual way of getting oxygen through liquid oxygen (LOX) or cryogenic systems comes with many problems. Buying LOX means needing big storage tanks and special transport setups. These not only drive up running costs but also create weak spots in the supply chain. Plus, deep cryogenic systems prove complicated and expensive to set up. They call for large starting investments and ongoing upkeep.

Why PSA Technology Is Gaining Attention

PSA (Pressure Swing Adsorption) oxygen generation has become a strong choice. It offers low running costs. When you stack it against buying liquid oxygen or changing bottled oxygen, compared to traditional oxygen supply methods, PSA oxygen generators are more energy-efficient over the long term.

DINAK has 20+ years of experience. We have focused on building and improving gas processing, separation, and liquefaction technologies. Our PSA products let you make oxygen right on site when you need it. This cuts reliance on outside suppliers.For smaller to medium smelting setups in particular, this tech gives a cheap, adjustable option with solid dependability.

Cost Analysis of Oxygen Supply Options

Comparing Lifecycle Costs

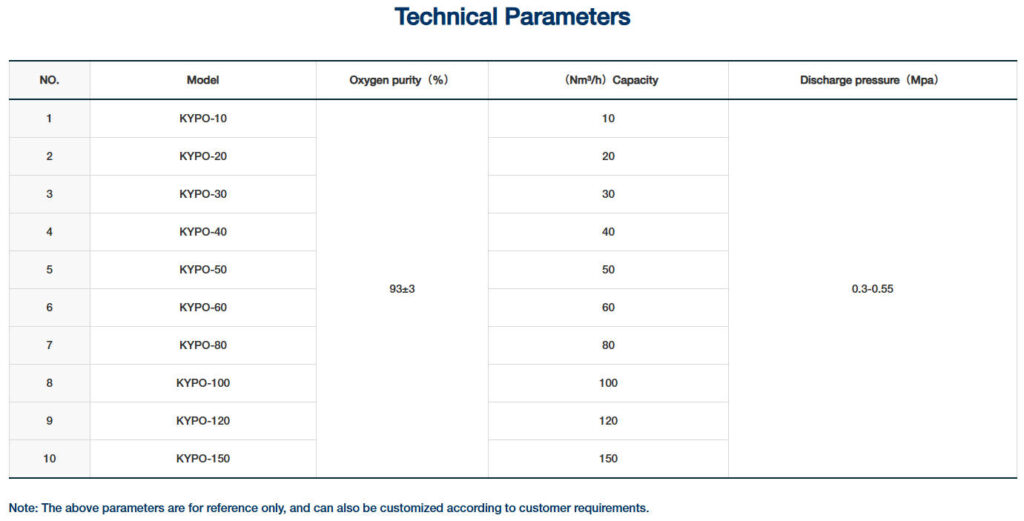

A full look at costs over the whole life shows that PSA systems do better than old supply methods in the long run. Cryogenic systems and LOX buys bring high upfront costs and repeated transport fees. But DINAK’s PSA units need smaller starting investments and use less power. They have low equipment costs and a quick payback time. Making oxygen on site skips the dangers of moving and storing gas. As a result, it feels safer and steadier. Take the KYPO series as an example. This line covers flow rates from 10 Nm³/h to 150 Nm³/h. It fits gas needs for various sizes.

Hidden Costs of Purchased Liquid Oxygen

Lots of smelters overlook the hidden expenses tied to buying LOX. These cover losses from evaporation in storage, fees for renting or buying cryogenic tanks, safety gear for dealing with high-pressure liquids, and wild swings in market prices. Such ups and downs create uncertainty in budgets. That can mess up financial plans.

ROI of DINAK PSA Plants

DINAK’s PSA plants come built for fast returns on the money spent. They offer high returns on investment, plus safety and eco-friendliness. Most often, people get back their starting costs in two to three years just from lower oxygen buying expenses.

Ensuring Stable Oxygen Supply for Smelting Operations

Risks of External Supply Disruptions

Depending on outside suppliers leaves smelters open to various dangers. Late deliveries from bad weather or transport snags can stop furnace work all of a sudden. Local shortages or fights over contracts add more threats to a steady supply.

Advantages of On-Site PSA Generation

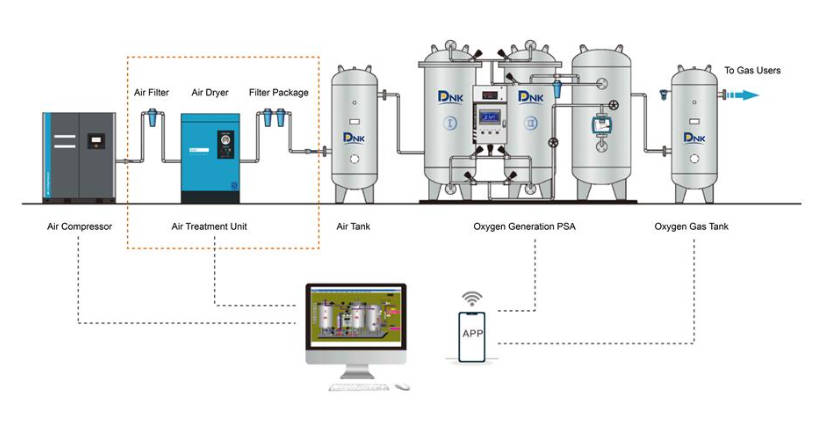

When smelters put in DINAK PSA systems right at their site, they take full charge of their oxygen needs. These setups run non-stop with very little break time. DINAK’s PSA units feature a modular design that allows easy expansion and quick installation. On top of that, DINAK adds smart PLC-based controls for steady work and far-off checks.

Meeting Variable Demand with PSA Flexibility

A main plus of PSA technology lies in how it handles shifts in production needs. You can adjust output to fit furnace loads or work shifts. This flexibility optimizes resource use and prevents unnecessary oxygen production during off-peak periods.

Key Features of DINAK Systems

Modular Design Benefits

DINAK’s PSA units have a build that lets you add parts easily for growth. If you run a small workshop or plan to grow bigger, you can tack on modules or tweak them without big changes to the setup. The compact modular design requires little space, has a short installation and commissioning cycle, and can be put into production quickly.

Energy Efficiency Advantages

Next to cryogenic systems or LOX vaporizers that run on huge compressors, DINAK’s PSA setups use far less power for each bit of oxygen made. This draws in users in areas where power rates hit profit hard.

Automation & Monitoring Capabilities

DINAK builds in full auto PLC controls with easy-to-use HMIs for simple handling. Fully automatic intelligent control enables one-button start/stop. User-friendly human-machine interface for intuitive operation. Live tracking features help spot issues early and plan fixes ahead of time.

Maintenance & Reliability Factors

Routine Maintenance Tasks

Upkeep stays simple: swap filters now and then, check valves, adjust the system. The modular design allows for rapid integration and scalability in industrial operations. You can get spare parts easily through DINAK’s strong support network after-sales. DINAK's engineers support customers in the best way and are the best partners for the smooth and efficient operation of the plant.

System Uptime Performance

DINAK’s PSA systems are made for top reliability and run continuously in normal conditions. The main molecular sieve lasts a long time, which keeps the whole setup steady.

Environmental and Safety Benefits

Producing on-site does away with truck hauls for LOX. That drops emissions from travel and losses from storage evaporation. The whole making process puts out no chemical waste, so it is safe and good for the environment. By skipping the handling of high-pressure cryogenic tanks or risky deliveries, DINAK’s PSA systems lift safety rules a lot in smelting sites.

Conclusion: A Strategic Investment for Smelters

DINAK’s low-cost PSA Oxygen Generator plants offer a real fix to the twin issues of high running costs and shaky supply that many metal smelters deal with these days. With deep and special know-how, we team up closely with clients across the globe. We craft answers fit to their wants that boost output, cut waste, and stretch equipment life over the full run. By allowing on-site making, these systems bring not only money back in a few years but also lasting freedom from outside sellers, better flexibility in work, and stronger stability in processes.

FAQ

Q: What purity level does the DINAK PSA system provide?

A: DINAK PSA systems typically produce oxygen at 93±3% purity, which is suitable for most metal smelting processes.

Q: Is the PSA plant suitable for small-scale smelters?

A: Yes, DINAK offers modular systems that are ideal for small and mid-sized smelting operations with variable demand.

Q: Can the output be adjusted based on production needs?

A: Yes, DINAK PSA plants allow flexible output adjustment to match real-time consumption levels.

Q: What maintenance is required for a DINAK PSA system?

A: Routine maintenance includes filter replacements, valve inspections, and periodic calibration—generally requiring minimal downtime.

-430x247.jpg)

内页小-430x246.jpg)