In industrial gas operations, attention usually focuses on major parts like the cryogenic cold box. This box plays a key role in liquefaction and separation processes. Yet, one vital system often gets little notice: the cryogenic storage tank. Although often overlooked in daily operations, it has a significant impact on long-term efficiency and operating costs.

Clients who buy air separation or liquefaction systems might not see how the storage tank choice influences product losses, energy needs, and upkeep expenses. This article looks at why picking a strong cryogenic storage tank, such as those from DINAK, goes beyond technical choices. It represents a strategic investment decision aimed at reducing long-term operating expenses.

Understanding Cryogenic Storage Tanks

What Makes a Tank “Cryogenic”

Cryogenic storage tanks handle liquefied gases such as oxygen, nitrogen, argon, carbon dioxide, and LNG at very low temperatures. Vacuum-insulated cryogenic liquid storage tanks and large atmospheric cryogenic storage tanks are the primary equipment used to store liquefied industrial gases and support downstream supply and distribution systems, depending on capacity and application requirements. They rely on high-vacuum multilayer insulation technology. These tanks are designed to minimize continuous heat ingress from the surrounding environment to avoid evaporation losses, called boil-off.

Key Components of DINAK Tanks

The structure of a cryogenic liquid vacuum storage tank includes an inner tank, an outer tank, a pipeline system, and safety accessories. DINAK tanks feature a double-layer setup:

- Inner tank: Typically built from austenitic stainless steel (such as S30408, equivalent to ASTM 304), which offers good toughness at low temperatures and corrosion resistance.

- Outer tank: carbon steel (such as Q345R, commonly used for pressure vessel outer shells in accordance with GB standards) forms the sturdy, protective outer layer that bears pressure.

- Insulating interlayer: Packed with expanded perlite and pulled to a high vacuum, this setup cuts down heat transfer by blocking conduction, convection, and radiation.

Every tank is supplied with a complete cryogenic process system, including filling lines, pressure control devices, safety valves, and level instrumentation.

Boil-Off Loss and Its Financial Impact

What Is Boil-Off Loss

Boil-off happens when outside heat turns stored cryogenic liquid into vapor. As a result, gas escapes and refills happen more often. This proves expensive, particularly for pricey industrial gases.

How DINAK Minimizes Boil-Off Loss

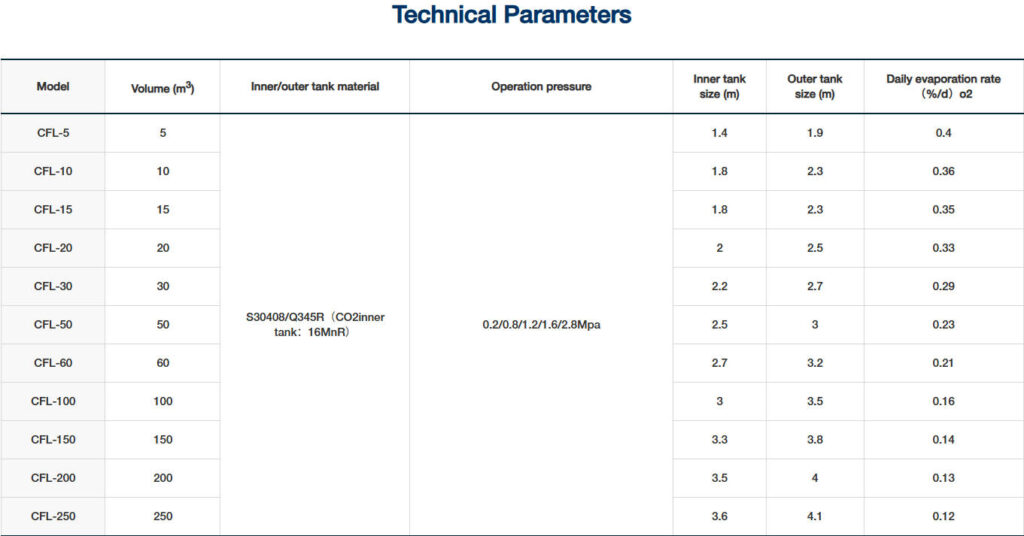

Modern high-vacuum perlite insulation lets the storage tank achieve an industry-leading low daily evaporation rate. This approach significantly reduces product loss caused by natural boil-off. Take the DINAK’s CFL-100 model, for instance. Its daily evaporation rate drops to just 0.16%. Meanwhile, the CFL-200 model hits only 0.13%, based on product details. Such low rates mean direct savings in operating costs.

Insulation Performance and Energy Efficiency

Importance of Thermal Insulation

Poor insulation boosts product vaporization. It also calls for more frequent cooling runs or added product. In the long run, this raises energy use and overall ownership costs.

DINAK’s Insulation Technology Advantage

The space between the inner and outer tank holds expanded perlite, and it gets vacuumed out. Paired with quality materials like S30408 for the inner parts and smart control systems, DINAK tanks keep inside temperatures steady. The improved design of the structure and pipes also limits liquid loss during pre-cooling and vacuum steps after the first fill or repairs.

Maintenance Costs and Long-Term Reliability

Common Maintenance Challenges

Cryogenic systems deal with valve wear, insulation breakdown over the years, and issues related to pressure stability and control. Repairs cause stops in work, which can result in significant production losses in continuous industrial operations.

How DINAK Reduces Maintenance Burden

DINAK tanks aim for dependability throughout their whole life. They follow pressure vessel rules closely in design and build, with top materials and careful work. The modular build makes checks and part swaps easier. Plus, DINAK provides after-sales help like remote checks, planned upkeep plans, parts supply, and staff training. All this keeps work disruptions low.

Total Cost of Ownership Considerations

Beyond Initial Investment Cost

Upfront costs often lead buying decisions. However, the true financial impact is reflected in the total cost of ownership (TCO), driven by day-to-day operational efficiency.. Factors like energy waste, boil-off amounts, repair needs, worker time, and fit with other systems all matter a lot.

Why DINAK Tanks Offer Better ROI

Built-in pressure controls and steady, smart running keep the gas supply reliable and ongoing. They cut down on hands-on work. Models such as CFL-20, CFL-50, or CFL-200 show low boil-off rates and solid builds. Users gain from fewer refills, shorter stops, and easier monitoring.

Integration With Industrial Gas Systems

Compatibility With Cryogenic Cold Boxes

As a maker focused on full gas handling systems, DINAK builds its tanks to fit smoothly with cold boxes in air separation plants. Cryogenic liquid storage tanks act as key support units in air separation plants. They offer vital buffering, load balancing, and backup gas supply during demand shifts.

Enhancing Overall System Efficiency

Matching storage size to needs helps even out supply and demand. DINAK tanks come in sizes from 5m³ to 250m³. This range fits different plant scales. They also allow changes for bigger volumes or unique needs. Such flexibility avoids delays in shipments or output.

Strategic Selection for Industrial Clients

Factors to Consider in Tank Selection

Selecting the best cryogenic storage tank means weighing several points:

- Needed storage volume.

- Insulation quality.

- Design pressure options (typically ranging from low pressure to up to 2.8 MPa, depending on gas type and application).

- Site setup (available space, weather).

- Fit with the gas type (e.g., LIN versus CO₂).

In real engineering work, choices for cryogenic storage tanks hinge on storage size, gas traits, pressure levels, and local conditions.

Tailored Solutions From DINAK

DINAK provides options shaped to specific client operations. These include material picks (like 16MnR for CO₂), connection standards, safety features (such as venting and spraying), and remote tracking. With over 20 years in the field, we create setups that boost both output and long-term worth.

Conclusion

A cryogenic storage tank does more than just hold material. It serves as a key resource that shapes operating costs, energy demands, and system steadiness. For clients building gas separation or liquefaction sites, choosing a capable tank from DINAK proves vital for lasting financial gains. By cutting boil-off, easing upkeep, and improving ties with main systems, DINAK tanks change how storage works. They enable sustainable, long-term cost optimization for industrial gas operations.

FAQ

Q: How does boil-off loss affect the bottom line?

A: Boil-off results in the loss of valuable liquefied gas, increasing the frequency of refills and operational expenses over time.

Q: What makes DINAK tanks more efficient than standard options?

A: DINAK tanks use advanced insulation technologies that significantly reduce heat ingress, minimizing boil-off loss and enhancing thermal stability.

Q: Can I integrate a DINAK tank with my existing cold box system?

A: Yes, DINAK tanks are designed for compatibility with various cryogenic cold boxes and can be customized for seamless integration.

Q: How often do cryogenic storage tanks require maintenance?

A: Maintenance frequency depends on usage conditions, but DINAK designs its tanks with durable components that extend service intervals.

Q: What should I consider when choosing a cryogenic storage tank?

A: Key factors include expected storage volume, desired insulation performance, site environment, and compatibility with existing equipment like cold boxes.

-430x247.jpg)

内页小-430x246.jpg)