Understanding Total Cost of Ownership (TCO)

When you look at nitrogen generation systems like PSA or membrane-based options, it's key to think about the Total Cost of Ownership (TCO). This covers the starting capital outlay, plus all the ongoing costs over the machine's working years. Those costs involve power use, upkeep, supplies, time lost from breakdowns, and even the final swap-out of the system.

While membrane generators may offer lower initial costs, they can lead to higher total costs over time due to frequent part replacements and increased energy consumption. So, when checking out DINAK nitrogen generators, go beyond just the PSA price tag. Include every cost from start to finish.

Why Compare PSA and Membrane Technologies

Knowing the gaps between PSA and membrane approaches is important for smart buying choices. These methods differ a lot in how they handle costs, power needs, upkeep timing, and overall dependability. Pressure swing adsorption (PSA) nitrogen generators are smart on-site tools that pull pure nitrogen straight from compressed air, all at normal room temperature. Membrane systems, by comparison, rely on thin hollow fiber membranes to split gases based on their size and movement speed. Looking at their TCO helps companies pick the right fit for steady work output, money plans, and green targets.

Initial Investment Costs

Equipment Purchase Price

PSA nitrogen generators usually call for a bigger upfront spend because of their detailed setup. This includes two adsorption towers, carbon molecular sieve beds, and smart PLC control setups. A full-pressure swing adsorption (PSA) nitrogen generation system has five main parts that work together: an air compressor, an air handling unit, an air buffer tank, the nitrogen generator main unit, and a control and monitoring system.

On the other hand, membrane nitrogen generators typically have a simpler design with fewer components, which may reduce initial costs but impact long-term reliability and efficiency. That means a smaller initial cash outlay. But it can mean lower purity and shorter life.

Installation and Commissioning

Because of their detailed build, PSA systems need more room and backup setups. DINAK’s modular styles cut down on this issue with smaller footprints. The compact modular design uses little space. It has a quick setup and startup phase. You can get it running fast. However, membrane units are often more compact and easier to integrate into existing systems. This cuts down on worker time and startup expenses.

Operating Expenses Over Time

Energy Consumption

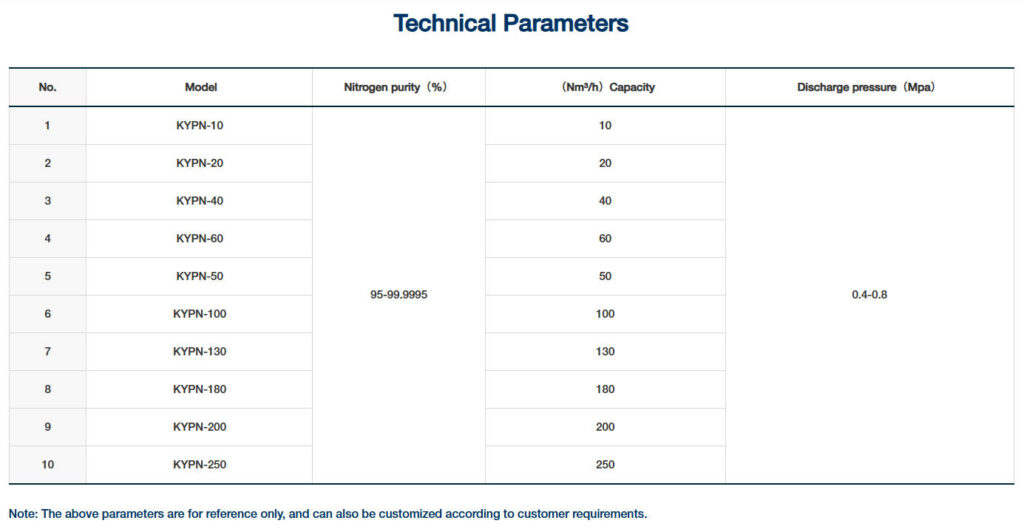

Power costs make up a big part of running expenses. The PSA process uses high-pressure air cycles. These take more electricity than membrane methods. Membrane nitrogen generators operate at lower pressures compared to PSA systems, which results in reduced power consumption but also impacts nitrogen purity and flexibility in production. At DINAK, our PSA generators like KYPN series’ capacity range from 10 to 250 Nm³/h, purity up to 99.999%.

Maintenance and Service Requirements

Upkeep routines vary a good deal between the two types. PSA generators need regular checks and, in time, a swap of Carbon Molecular Sieve (CMS) is an essential component of PSA nitrogen generators, acting as a filtration medium to separate nitrogen from other gases. Under regular conditions, it lasts more than 10 years. Membrane modules wear down from dirt in the incoming air. They usually need a full change every 3–5 years, based on how they're used.

Downtime and Reliability Impact

System Uptime Considerations

DINAK’s PSA nitrogen generators are made for steady running. They use smart controls and backup from dual towers. The alternating cycle means two (or more) adsorption towers switch via exact valves. They go through “adsorption” and “desorption” steps. This setup lets the whole system keep putting out pure nitrogen without stops. Membrane systems have fewer parts that move. But they can suffer more from dirty air and slow breakdown. These issues cut into running time, especially in tough factory settings.

Impact of Downtime on Production Costs

In nonstop factory work, sudden cuts in nitrogen flow can cause pricey holdups or lost goods. When figuring TCO, add in not just fix-up costs but also the hit to output from failures. Besides power bills during daily runs, you face costs from stoppages, fixing work, repairs, and handling spare parts. These add up fast.

Lifespan and Depreciation Value

Expected Service Life of Each System

DINAK’s PSA nitrogen generators are designed to last. They often run well for 10–15 years. Their solid build and auto error spotting help push out their useful time even more. Membrane-based systems usually need a full swap after 7–10 years. That's due to steady wear on the membranes.

Depreciation Implications for Budget Planning

Gear that lasts longer, like DINAK’s PSA systems, lets you spread out capital spending over more years. Shorter-life membrane options might look cheap at the start. But they mean you replace assets more often.

Conclusion

Picking between membrane nitrogen generators or DINAK’s PSA takes more than checking the buy price. A full TCO review shows that membrane units save money at the outset. However, they can lead to larger bills over the years from poor power savings and regular part changes.

For fields that need pure nitrogen, reliable runs, and long work life—like food packaging, electronics making, or metal work—DINAK’s PSA nitrogen options give better value for money. We draw on more than 20 years of experience in gas handling tech to build setups that fit what customers want. These help boost workflow, cut waste, and keep things going strong over the full plant cycle.

FAQ

Q: What is the total cost of ownership for a nitrogen generator?

A: It includes purchase price, installation costs, energy usage over time, consumables like CMS or membranes, maintenance frequency, impact of unplanned downtime, and expected equipment lifespan.

Q: How long do DINAK PSA nitrogen generators last?

A: DINAK PSA generators typically last 10–15 years with consistent performance.

Q: Are membrane nitrogen generators cheaper than PSA?

A: They often have lower initial pricing but may incur higher cumulative operating costs due to frequent component replacements and less efficient energy use.

Q: How often do I need to replace parts in a nitrogen generator?

A: For DINAK PSA units, CMS may last 5–10 years; for membranes, modules usually require replacement every 3–5 years, depending on feed air quality.

-430x247.jpg)

内页小-430x246.jpg)